| MVR film evaporator |

MVR EVAPORATOR

Application:

Mechanical vapor recompression (MVR) evaporator used is used for milk, glucose, organic acid, VC, xylose, pharmaceutical, chemical, biological engineering, environmental industry, waste recycling industry, paper making industry, salt making industry and so on.

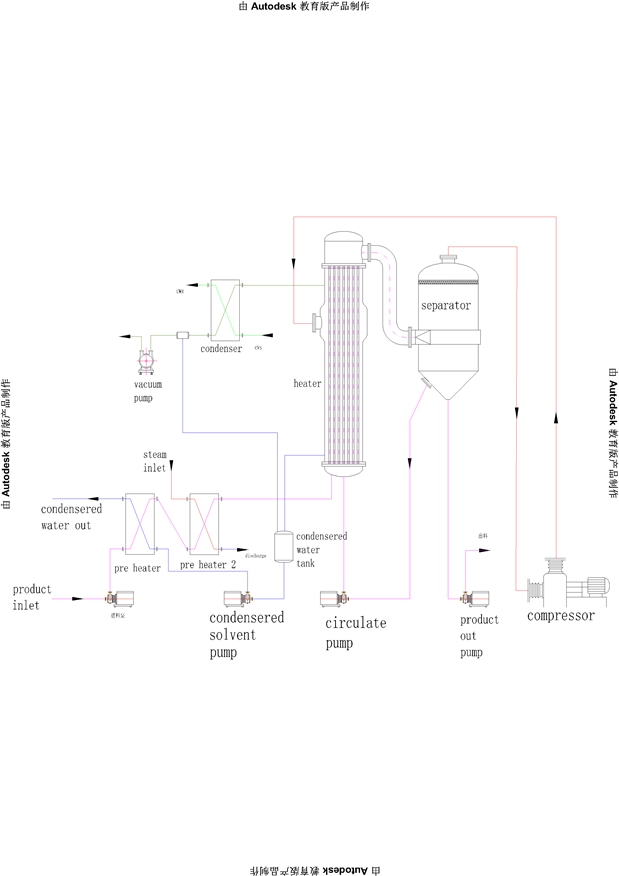

Structure Drawing:

Structure: MVR evaporator includes pre-heater, heater, pump, separator, vacuum system, compressor system, automatic control system, cleaning system and so on

Principle: To feed the material from raw material storage tank through feed pump, the preheating system and the heating system into the heater and the separator. To stop feeding when the liquid level reaches the setting height.

Then to start material circulating pump, the liquid will be circulating in the heater and the separator, to open the steam valve to heat the raw material, when the temperature is reaching the setting temperature, then turn on the vacuum system and compressor, the impeller speed is gradually increasing, then the system is evaporating, at the same time, the raw material is continuously entering from the bottom of the heater, it is like film flow from bottom to up, it is also heated by steam until boiling, the steam is spraying out from the arc guide groove to separator, the steam will be rotating rise along the wall of the separator and exhaust into compressor, the liquid will drop down to bottom of the separator. The temperature of pure steam will rise after compression, this recycled steam can heat the heater again, so it can save energy. The recycled steam will be cooled and became into hot water which flow into pre heater, to heat the raw material which flow into heater and separator, so the whole system maintained at a constant feed, discharge, evaporation.

Character:

MVR evaporator is new technology for modern industry

1. MVR Evaporator saving technology is the most advanced of the current international evaporator technology requires only a very small amount of Health and steam (when start up, need a small amount of steam, normal operation, is almost no need for the steam), greatly reduce business operating costs, reduce environmental pollution.

2. As a result of compressors to provide heat, and compared to conventional evaporator, the temperature difference is much smaller, to achieve a moderate evaporation, which greatly improve product quality and reduce fouling.

3. No condenser or only a small area condenser, structure and process is very simple, fully automatic, continuous operation, safe and reliable.

4. Equipment with CIP cleaning within the pipeline can be realized inside cleaning, the entire device easy to operate, no dead ends.

5. The evaporator is a material at low temperatures ( evaporation temperature 45℃-75℃ )and does not generate foam under the state of evaporation, liquid evenly, do not run material, not easy to coking, minimum denaturation for heatinf material

Parameter:

|

Model |

MVR-0.5 |

MVR-1 |

MVR-1.5 |

MVR-2 |

MVR-5 |

MVR-10 |

MVR-15 |

|

Evaporation capacity |

500kg/Hr |

1000kg/Hr |

1500kg/Hr |

2000kg/Hr |

5000kg/Hr |

10000kg/Hr |

15000kg/Hr |

|

Inlet聽 saturated steam capacity(kg/Hr) |

500 |

1000 |

1500 |

2000 |

5000 |

10000 |

15000 |

|

Inlet saturation temperature (c) |

55.295 |

71.631 |

82.109 |

90 |

90 |

90 |

90 |

|

Outlet temperature (c) |

12.590 |

14.145 |

15.185 |

16.000 |

16.000 |

16.000 |

16.000 |

|

Outlet the saturation temperature (c) |

67.885 |

85.776 |

97.294 |

106.000 |

106.000 |

106.000 |

106.000 |

|

Inlet saturation pressure kPa (A) |

15.975 |

33.441 |

51.567 |

70.117 |

70.117 |

70.117 |

70.117 |

|

Inlet saturation pressure kPa (A) |

28.432 |

59.596 |

91.921 |

125.029 |

125.029 |

125.029 |

125.029 |

|

Compression ratio |

1.780 |

1.782 |

1.783 |

1.783 |

1.783 |

1.783 |

1.783 |

|

Motor power (kw) |

40 |

55 |

75 |

95 |

132 |

550 |

640 |

|

Outlet volume flow (m^3/s) |

0.795 |

0.7971 |

0.7985 |

0.7997 |

0.7997 |

0.7997 |

0.7997 |

|

exhaust velocity(m/s) |

22.736 |

22.795 |

22.837 |

22.87 |

22.87 |

22.87 |

22.87 |

|

Outlet volume flow (m^3/s) |

4X4X10 |

6X4.5X12 |

8X5.5X14 |

8X5.5X14 |

9.5X6X15 |

12.6X6.5X17 |

13.6X7X17 |

Order requirement:

What is your raw material?

How much is original degree of raw material?

How much the finished degree of product do you want to get?

How much liter do you want to evaporate per hour?

When do you need this machine?

Copyright © RuiAn global machinery co ltd Copyright.All Rights Reserved.