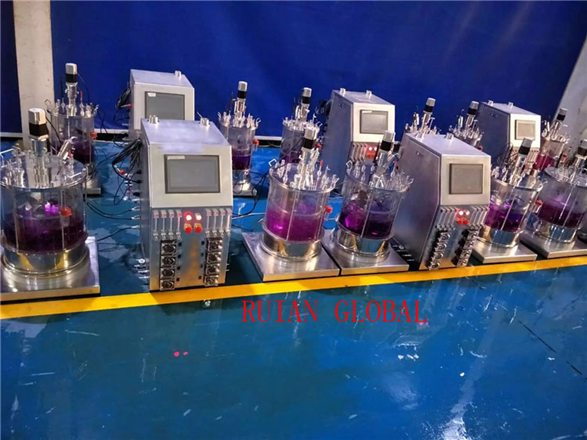

| glass fermenter |

Glass fermenter

一、 System constitute:

|

No |

Item |

Description |

|

1 |

Vessel system |

Total volume: 71itres, Working volume: 3-5liters Strainless steel cylinder combines with glass partly. It uses a large area of highly refractory glass to observe material easily. Magnetic force stirrer without axes sealing. There is no possibility to leak out the bacteria. The view is spacious. The agitation system is hanged up. There is no thimble at the bottom. Ratio of diameter to high: 1:2 |

|

2 |

Sterilization method |

Off-site sterilization autoclaves |

|

3 |

Aeration system |

Include rotameter, aeration filter |

|

4 |

Agitation system |

GJ:Mechanical sealing system at the top of the fermenter; high-powered stirring oar, antifoam oar; AC electrical machine: infinite speed variation; rpm in the 1L germ fermenter: 70~1000rpm±1%,The height of the stirring oar can be adjusted, too. |

|

5 |

Temperature control |

Interlayer electric calefaction, auto-control |

|

6 |

Airflow control |

Manual control, Flow meter display |

|

7 |

Anti foam control |

Automatically check foam, automatically add antifoam by peristaltic pump. |

|

8 |

Feeding control |

Control by peristaltic pump switch, automatically feeding and computation. |

|

9 |

pH control |

Automatically add acid, alkali by peristaltic pump and control pH accurately. |

|

10 |

DO control |

Control with rotating speed relatively. |

|

11 |

BLBIO-B Biology process controller |

Control parameter: temp, pH, DO, antifoam, stirrer rev, feeding; |

|

Control system |

BLBIO B Control System: on-site controller, the next crew for the Siemens S7-200 series PLC control system, it is a mature, stable, universal type of PLC, to suit a variety of automation applications, especially in manufacturing process control Application. Its modular, easy to implement distributed configuration and easy to master and so on, Siemens PLC control center has become a biological reaction process control implementation is economical and advanced control system, the system uses the touch screen display, on-site direct operations (menu type), all English menu and interface; also with the host computer for data transmission, data sampling and display tank, the system view of data analysis, reading settings. 10-inch LCD touch-sensitive screen as the display screen to display complete content-rich, user-friendly screen is simple, easy to operate. And disturbing each other. The control system can adapt to different range of sensors and actuators the output of the input signal with the signal anti-jamming system. Software: Siemens S7+ FORCE CONTORL Data collection and control module: Siemens S200 PLC controller and data collection and control module 1. Control 2. Measurement function: can feeding, bubble enemy, such as measurement of pH 4. Data Processing 5) data storage format is compatible with EXCEL, EXCEL platform can be to deal with 9. show the controller is really running against, the panel instructed the state process system, process hardware, and motion status indicator for understanding the various devices (such as peristaltic pumps, circulating pumps, heating, mixing, etc.) work status, Fault identification can be used as display | |

|

11 |

PC software |

BLBIO-Ver8.0 is a data recording and processing as one of the fermentation of special packages, with the English operation interface, data storage and backup, curve analysis, report generation analysis, anomaly analysis, for the fermentation and production process control and data processing bring a lot of convenience. 6. Report Printing 7. curve printing |

二、 Technical parameter:

|

No |

Parameter |

Guideline |

Controller data processing function |

|

1 |

PH |

Displaying range: 0.00~14.00±0.01 Auto-control range:2.00~12.00±0.05 Fermentation process control (According to the fermentation time, auto- control pH fluent, at least10 parts) |

pH value historical and trend curve analysis Acid, alkali dosage curve analysis Batch report form analysis Acid, alkali total dosage record Keep and deliver data |

|

2 |

DO |

0-150±3%,Displaying precision: 0.1% It can be controlled by rev and feeding. Fermentation process control (According to the fermentation time, auto- control DO fluent, at least10 parts) |

DO value historical and trend curve analysis Batch report form analysis Keep and deliver data |

|

3 |

Antifoam |

Automatic PID control and alarm Fermentation process control (According to the fermentation time, auto- control antifoam fluent, at least10 parts) |

Antifoam value historical and trend curve analysis Foam error state record antifoam total dosage record Batch report form analysis Keep and deliver data |

|

4 |

Rev |

Automatic enactment and control(50~1200rpm±5‰) Fermentation process control (According to the fermentation time, auto- control rev fluent, at least10 parts) |

Rev value historical and trend curve analysis Batch report form analysis Keep and deliver data |

|

5 |

Temperature |

Temperature of cooling water: +5℃-60℃±0.1℃ Fermentation process control (According to the fermentation time, auto- control temperature fluent, at least10 parts) |

Temperature value historical and trend curve analysis Batch report form analysis Keep and deliver data |

|

6 |

Feeding |

PID automatic enactment and control Fermentation process control (According to the fermentation time, auto- control feeding fluent, at least10 parts) |

Feeding value historical and trend curve analysis Feeding total dosage record Batch report form analysis Keep and deliver data |

|

7 |

Pressure |

Manual control, instrument display |

|

|

8 |

Air flux |

Manual control, instrument display |

Material and brand of key components

|

No. |

Key component |

Material and brand |

Quantity |

|

1 |

Vessel system |

The cylinder designed by our company uses stainless steel combined with glass partly. Stainless steel:Glass: borosilicate glass. The framework is advanced. |

1 |

|

2 |

Buncher |

High grade aluminum alloy |

1 |

|

3 |

Speed regulator |

Panasonic, Japan |

1 |

|

4 |

Solenoid valve |

Taiwan |

1 |

|

5 |

Aeration filter |

0.2μm, SARTORIUS, Germany |

2 |

|

6 |

Breathing filter |

0.2μm, SARTORIUS, Germany |

8 |

|

7 |

pH electrode |

Switzerland |

1 |

|

8 |

DO electrode |

Switzerland |

1 |

|

9 |

Peristaltic pump |

lange |

4 |

l Working environment:

l Up to the internal &external environment required by fermentation

l Up to the technic-required water supply. The temperature of cooling water is at least 5℃ below the temperature of fermentation

l Power requirement: AC220/2KW

l Compressed air: Primarily-processed compressed air, relative humidity:≤60%,ventilatory capacity is accorded to the technics.

Copyright © RuiAn global machinery co ltd Copyright.All Rights Reserved.